I’m lucky to work with some amazing bath, body and candle brands and some of the coolest gourmet food companies on the planet. Many of those are startup brands who are bootstrapping the way to their dreams. Working with limited funds, many of my clients print their own labels (with the help of https://gmplabeling.com/) in order to save money. When one actually pauses to crunch the numbers on the label material, toner, wear + tear on your printer and the time invested to print labels sheet-by-sheet, professionally printed labels usually come out ahead of the pack on price and they always come out ahead on quality.

I long ago learned the secret to affordable label printing, and I’m excited to share a few tips that might put those swanky pro labels within your reach a lot sooner than you imagined. First, a few terms which will make your toes tingle:

DIGITAL PRINTING:

The process of using laser technology to apply ink to the label material. Traditional printing uses metal plates to apply the ink, and those plates don’t come cheap. Even an insignificant change in label art (reworking a sentence, correcting a typo, changing a fill weight) necessitate a completely new plate. For creative brands running a fairly small number of labels, digital printing is the way to go.

GANG RUN PRINTING:

The process of combining several print jobs with a professional printer in order to tap the economies of scale and reduce the cost-per-piece of each label.

DIGITAL + GANG RUN PRINTING = CHEAPER THAN YOU CAN PRINT AT HOME

I have two digital, gang run printers that I recommend: Lighting Labels and Frontier Label. Both offer low minimums, free sample packs, a variety of label materials, instant online estimates, and quick turnaround times. Let’s take a look at the power of digital gang-run printing to reduce the cost of professional printing. I played around with Frontier’s instant online estimator…

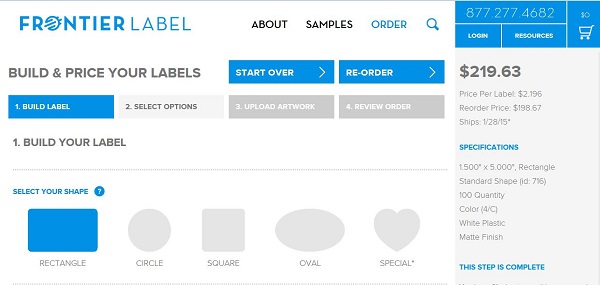

I selected a random label size (2″ x 6″) and ran it through a few scenarios at Frontier Label. Initially, I selected one label design on white plastic with a matte finish in a quantity of 100 pieces.

Total cost for the job? $221 and change. Yeeeouch! That equates to $2.21+ per label. No thank you. But what if I could bump that label order from 100 to 500 pieces on a single run?

The total cost for the job increases, of course. But let’s look at that estimate a bit closer, shall we? You might expect that if 100 labels set you back $221ish dollars, that 500 labels might cost five times as much, or around $1,000. But that’s the beauty of any type of professional printing… as the quantity increases, the price plummets. At the 500-piece mark, our labels have decreased from $2.21 each to just $.50ish cents per piece. Hells yes! Let’s push this experiment a little further and see what happens.

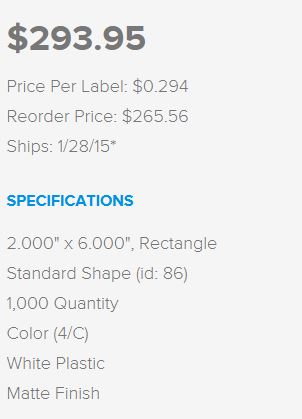

1,000 labels? We’ve gotten these bad boys down to less than 30 cents per label! Same size. Same printer. Same material. And we’ve knocked 85% off the price when ordering 1,000 labels versus 100 labels. One more time for good measure…

At the 2,500 piece mark, we’ve nearly cut our costs in half again. These labels are deliciously priced at just 16 cents each. As an entrepreneur and business strategist, almost nothing makes me happier than seeing the economies of scale in action!

Yes, but what if you don’t need 2,500 labels?

Ah, that’s the beauty of digital gang run printing! Let’s say you own a gourmet pecan company (a tip of the hat to Molly & Me, who make some deliciously tasty pecans that make my Southern heart happy). If you create 5 varieties of pecans and you sell all 5 varieties in the same packaging (a clear glass jar, for example), then you could create 5 labels which are all the same size. The art can vary so long as the label size and material remains consistent. So your label order might look like this…

- Cinnamon + Sugar- 100 labels

- Roasted + Salted- 100 labels

- Praline- 100 labels

- Sugar + Spice- 100 labels

- Sweet Heat- 100 labels

With the snap of a finger, Molly & Me could order 500 labels- 100 of each variety- and tap that 500 piece price of just 50 cents per label. On her next run, as the business grows, she could order 200 of each label- or 1,000 total combined labels and hit the 30 cent mark. Pretty groovy, eh?

MONEY-SAVING LABEL STRATEGIES

1. CHOOSE DIGITAL PRINTING. As your order volume increases (think tens of thousands) there will likely come a time when traditional printing with metal plates makes the most financial sense. In the meantime, select a good digital printer for the best pricing. Ring up Lightning Labels and Frontier- they’ll both be happy to send a complimentary sample pack your way.

2. SELECT AS FEW PACKAGING STYLES AS NEEDED TO STREAMLINE THE NUMBER OF LABELS SIZES. If your line utilizes 6 kinds of jars and 4 styles of boxes and 3 cardboard tubes, then you’ll need 13 unique label sizes, none of which can be gang run. Consolidate whenever possible.

3. CHOOSE AS FEW LABEL MATERIALS AS POSSIBLE IN ORDER TO TAKE ADVANTAGE OF GANG RUN TECHNOLOGY. Even when running the same label size, if the printer has to stop the presses and switch the label material, the gang run pricing doesn’t hold. For example, in my 2″ x 6″ label example (above), if half of my labels were run on opaque white label stock and the other half where run on clear label stock, then I wouldn’t be able to combine runs and take advantage of the cost savings.

4. CHECK AVAILABLE DIE SELECTION BEFORE YOU START THE DESIGN PROCESS. Think of a “die” as a paper punch. It cuts the shape of out the roll of label material. Most good printers have hundreds of label dies from which to choose, and they’re usually happy to make any custom shape or size needed. The good news? You only need to buy the die once and you can use it again and again on future runs. The bad news? The dies don’t come cheap. They typically range from $150-500, so first check to see if there’s an existing size you can utilize at no cost before you begin the label design process.

5. CHOOSE PDF PROOFS ON SECOND AND SUBSEQUENT RUNS. The process of “proofing” a job is important. Press proofs are physical samples created on the exact machine the printer will use for the big run, and mailed to you for approval. They’re awesome and enable you to hold a physical sample in your hands before you sign off and authorize the run. You can check the color, the fit on your packaging, the durability of the label stock, etc. I highly recommend press proofs when running a new label desig, but they usually cost a wee bit extra, plus overnight shipping fees. On the first order? Get that press proof. On your next order of the same label, settle for a PDF proof which can usually be delivered digitally the same day you place the order. You already know the color, label substrate and fit are right, so at this point you’re just checking to ensure that the proper label art is being run.

6. THINK AHEAD TO AVOID COSTLY MISTAKES. Read your labels several times to check for typos. Read them backwards. Hand them off to a friend (or three) and have them double-check them. When you and I are enjoying a cocktail sometime, remind me to tell you the story of how I once printed 5,000 “body mouse” labels… which should have read “body mousse.” I cried for days.

Also, cut out a piece of paper in the exact size you plan to print and physically tape it to your packaging to ensure a good fit. Finally, order a sample pack before you get started so you can choose the most suitable label material for the job.

First impressions count for a hell of a lot with creative brands. Put your brand’s best foot forward with smartly designed, professionally printed packaging and I guarantee you’ll “level up” your biz game. If you have a favorite label printer, I’d love to hear about them in the comments below!

True story: I launched my bath + body brand in 2003. In the process of planning my wedding in 2004, I realized that we were about to blow an obscene amount of money on a party, though my fledgling new business was probably a better place to invest those dollars in the long run. I convinced my fiancée to forgo the wedding, and we married at a justice of the peace, plowing that money into my first run of professional labels. The business took off, and I remind him of what a fantastically good decision that was every time we’re parked on a beach in the Caribbean sipping cocktails. 🙂

The most difficult part for us is always streamlining labeling types. What if we want bags for herbal sachets and jars for bath salts and glass jars for facial creams and tiny tubes for perfumes and boxes for soaps and, and, and…? I think these tips will help us start out on the right foot as we consider expanding our product offering.

Great tips Lela! Packaging is SO important. The thing I find hardest is the color matching from run to run, and also between different substrates (for ex. cardboard cartons vs. sticky labels). Our latest printer, Logic Pakaging, has done a good job of color matching for us, but they only make cartons. Do you have any recommendations for printers with awesome color matching capabilities that do both cartons AND labels? I’ve had some real losers in the past where the color matching was downright horrible even on the same kind of substrate! EPIC FAILURES.

Great advice. You may also want to add Leaping Lizard Labels to your list…not only do they do small runs (even smaller than the ones listed above), they also allow you to choose any size you want…not just standard sizes.

Hi Shelley,

Thanks for the Leapin’ Lizards recommendation. I have spoken with them and received a sample package as well. While I thought their customer service was stellar, I didn’t find the print quality to be “on par” with Lightning and Frontier. Thanks for throwing their name into the ring!

Cannot stress how important enough it is to do Prepress and check (and re-check with another set of eyes!) your labels’ soft proofs before going to press to avoid costly errors. Before committing to a job, best to always get samples to check for material, print quality, and laminate options; and yes, take advantage of price breaks with higher quantities if you won’t be changing your label design in the near future. That adds up to a lot of savings!

I would also mention that on the press proof / hard proof, colors on gang run would have a shift of 10%, but that would be within industry standards (this is inherent in gang run). To cut time going back and forth, always submit layered files in vector (Illustrator or InDesign files), and not raster (as with Photoshop), in CMYK mode, to keep the integrity of your art elements. Re-check color values using your brand’s style sheet for accuracy before submitting files. Also make sure your TIC (total ink coverage) is set to your printer’s standards so that they won’t need to adjust color values that can make the whole process more tedious for both parties.

At our office, Prepress checks and revisions are free of charge, precisely because we’ve encountered many cases wherein our customers would immediately want to print without preflighting, until we explain the value of the Prepress check. This is comprehensive, and a great resource for anyone who is looking to get started with printing custom labels!

Thank you for this informative article. We started a home based business for our adult son with autism, because we were told he was unemployable. We make personal care products and he is thriving. His enthusiasm for work is inspiring. Our business is growing, but we’ve been told repeatedly we should have our labels printed professionally instead of printing them ourselves. No matter what company I try, the huge quantities required to get that per label cost comparable to printing them ourselves, send me running. Your article is the first I’ve heard of gang run ordering. If we can truly get all 6 scents of each product to count toward the 1000-3000 count, that just might make it doable for us! Now, if we could just firm up a design we are ALL happy with. 😉

I recommend Avery WePrint. Obviously, Avery Labels, duh. Now they do custom printing on digital presses. Cute little tags and cards too. Their labels and customer service can’t be beat. You can do everything online and then if you need to you can also print yourself. Best quality labels. And if you are doing custom printing they will fix mistakes for you and let you know.